1.tri-proof polyester filter cloth of good durablity 2.high temp resistant filter cloth 3.anti-static filter cloth

Chemically resistantHydrophobic Low background, interference-free chemical determinations Low tare mass for accurate gravimetric results Autoclavable SUITA PTFE filters Polypropylene PTFE Filter Cloth are strong and completely resistant to acids, bases, and all solvents. Use PTFE filters when sampling in aggressive environments.

Specifications 1.good air permeability, 2.Flat&smooth surface 3.good resistance to acid&alkali.

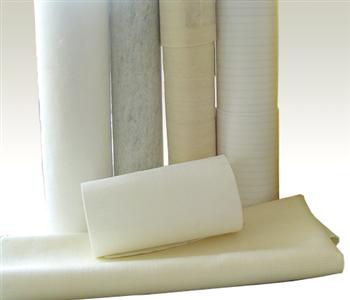

Specifications We manufacture the polyester needle felt for air filtration. Weight available:350gsm-650gsm ,various finishing availablp

Polypropylene Filter Farbic Composition: polypropylene Construction: Staple/staple, Mono/mono, Multi/multi, Multi/mono Weight: 200gsm-750gsm Air permeability: 20-2500 L/M2.S@200Pa

Specifications recycled needle punched felt 1.PE film for coverage to anti-slip 2.dustproof,dampproof 3.High quality and fine price. We are one of the most professional nonwoven fabric manufacturers in China.

It is widely used both in dry and wet filtration. Cares must be taken against hydrolysis by hot alkali. Our Polyester needle felt with various finishing treatment: Heatset,singed,calendered as the standard finishing treatmet.

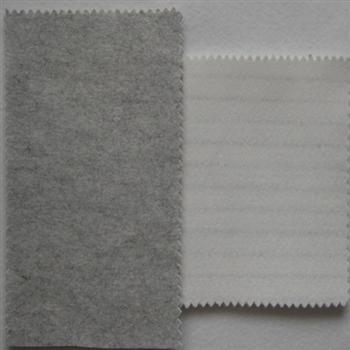

Polypropylene Needle Punched Felt Polypropylene fiber is the lightest and the most easily to process among all the synthetic fibers.Acid proof and alkali proof is great.It has stability, high tenacity, and small elongation. Because of its smooth and porous surface and large air permeability, it has the characters or small vacuum resistance.

PP needle punched filter felt has more advantages when compared with PET needle felt. It is acid and alkali resistant, and has low intenerate point.

Polyester filter felt 1Delivery time:10-15ds 2Width:2m 3Certificate:ISO9001:2000&100%PE 4MOQ:150m&FOB-SH:1-25us

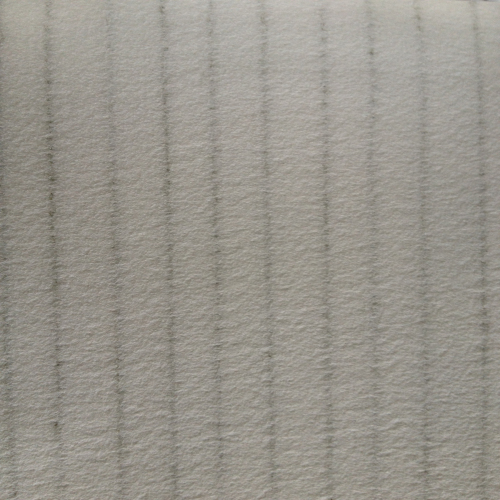

During the weaving process, we add the anti-static yarn regularly. It is used for explosive industry dust collection to prevent explosion caused by static flame during the production. It is also used for solid-liquid separate. For some sticky filtrate, it makes cake removing more easily. We generally adopt the stainless steel fiber for anti-static

anti-static felt specifications: Product name:anti-static polyester needle felt(anti-static scrim) Material: polyester staple fiber Scrim:polyester anti-static scrim

Tensile strength (n/5 x 10cm): a) Warp: 1,000 b) Weft: 1,200 Tensile elongation: a) Warp: <20% b) Weft: <25% Permeability (10-3m3/m2.S): 150 - 350 Working temperature (oC): a) Continuance: 130 b) Instant: 150 Surface treatment: singeing, calendering, heat setting

Except technic to manufacture common needle punched felt, it also require to replant electric conduct fiber into the scrim or blend the chemical fiber with electric conduct fiber and other electric conduct material. Our company can make both filter needle punched felts.

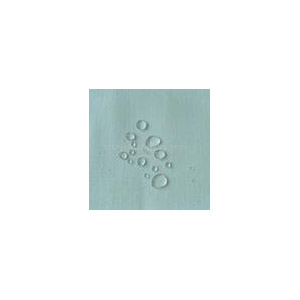

During the running of dedusting bags, the gas includes moist, hygroscopic and deliquescent powders. It will create the water or oil membrane on the surface of powder to increase the cohesion, but it will make the dust removal more difficult. After treatment, those filter material can form the molecular barrier around the fiber