Liquid Filter Bags

Dust Collection Filter Bag

1 excellent heat resistance, 2 flame resistance, 3 high temperature dimensional stability. 4 good chemical resistance

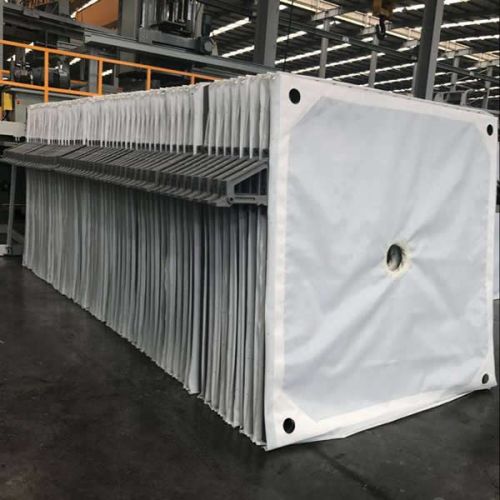

Filter press Cloth bag

DIASTAR FILTER CLOTH

Kelly filter bag

Reliable Filter now has the capability to apply a complete variety of chemical treatments to its range of filtration felt media. The ability to apply these finishes can considerably improve a felts performance, efficiency, and life expectancy.

We offer a complete line of dust collector bags to fit most manufactures' filter bag housings. Our filter bags are carefully fabricated and sized to ensure ease of installation and change-out. These filter bags are designed to be mounted and gasketed firmly into place with a snap band, corded cuff

GAUDFRIN DIASTAR FILTER CLOTH FOR ALUMINATE LIQUOR CLARIFICATION

Liquid Filter Bag Our liquid filter bags are produced of fabrics and needle felts in different fineness according to your filtration process. They are well designed to meet your specific filtration requirements.

Mesh Filter Bag Material Nylon (polyamide) or polyester monofilament / multifilament mesh Process Sewn / welded Micron Rating 10~ 800 Mouth Type Steel ring / plastic collar / draw string Size Standard sizes and custom size available

Specifications Eco-friendly non woven making bag 1.acid resistance,alkali resitance. 2.easy cleaning.

For more and more strict demand on filtration precision, we developed welding filter bag. The welding filter bag is made of high-grade polyester and PP felt .The surface is singed to avoid fiber falling which will cause pollution to the filtrate. The felt is Needle Punched which could provide three-dimensional filtration.

Filter Bag Cleaning is made of polypropylene micron-fiber, which is chemical stable and with high power- capturing ability in Micron Grade. It can provide absolute high ability in filtration and tolerance. With filtration precision of 99.9%, HEPA filter bag is suitable for most industrial fields.

Press cloths cover a wide range of filter press designs from single cloth, drape over cloths, duplex or barrel-neck cloths and caulk-in cloths. Although the designs are different, th e basic filtration function is the same whether it is an old plate and frame or a new recessed chamber, caulk-in automatic press with diaphragm squeeze.